No products in the cart.

discovering new ways

Sustainability starts at home. Therefore, our desire to help the environment comes from the design of our products.

our plastic

AlpFilm Protect was developed to avoid food waste and save resources and money.

our plastic

AlpFilm Protect was developed to avoid food waste and save resources and money.

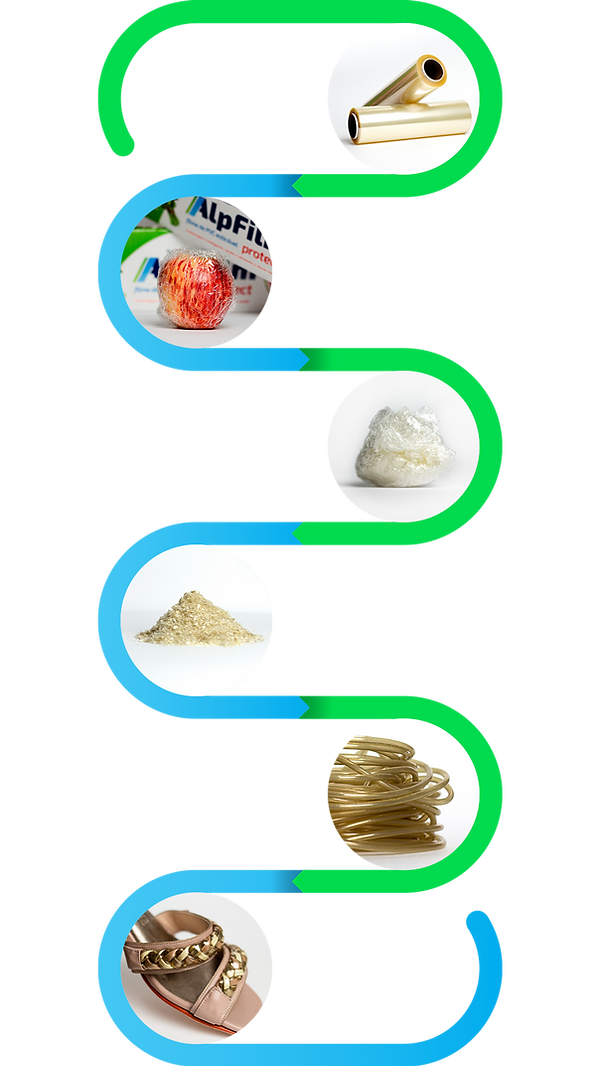

PVC Film Recycling

Alpfilm, through the AlpfilmCycle project, recycles post-consumer PVC film.

This material is collected in restaurants and fast food outlets in shopping malls by a partner cooperative. After collection, Alpfilm sanitizes the plastic and subjects it to a high-temperature grinding process to eliminate any contamination.

Then, micronization occurs and mixing with other new PVC products, resulting in a quality raw material in powder form. This recycled raw material is transformed into colored grains through the addition of dyes. Finally, these grains are used in the manufacture of the beautiful orange toiletry bag from AlpfilmCycle.

It's incredible to see how Alpfilm contributes to sustainability by recycling this material.

And how does it work?

Our plastic film has elasticity, that is, the probability of it tearing is very small. It is resistant: you won't need to go through layers and layers of plastic to protect a food, for example. In addition to all this, it is antibacterial and guarantees 99,99% protection against bacteria and fungi, increasing the shelf life of the food and avoiding contamination.

After consumption, where does this plastic go?

Thinking about sustainability, we created a reverse logistics process aimed at large businesses. In partnership with Cooperativa Cooper Viva Bem, we collect plastic film used in restaurants and, in the future, we intend to establish new partnerships like this one.

Despite being a great challenge, our research has shown how to make post-consumer plastic film recycling feasible.

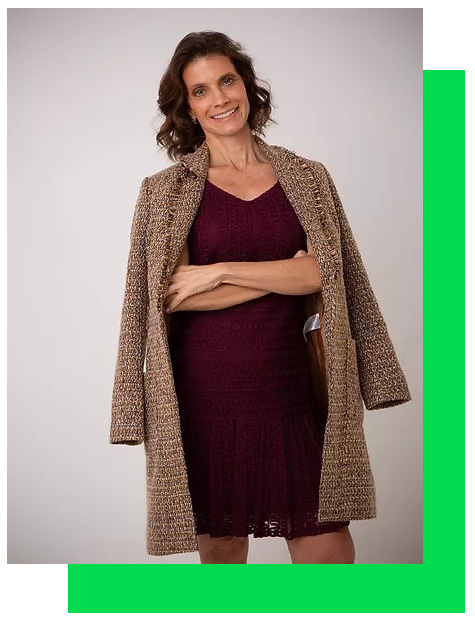

It is possible to transform it into materials that can be used — at this first moment — in the fashion industry and in craft products.

In the photo to the side, Boutique Patrícia Camacho used the braided material as an adornment in the shoes.

Creating a new story

The sooner we understand that each material has its properties and that each one of them can act in the construction of different products, the sooner we will have the results of a healthy world.

Nature has a cycle: it is up to us to interpret it and work to ensure that it is respected in all our actions.

We can, together, redefine the use of post-consumer plastic film in the industry and, thus, build a more sustainable future.

Partnerships that transform

“Alpes has always been concerned with sustainable actions. This started when we launched on the market a plastic film with high elasticity, resistance and that, therefore, made the consumer use only what was necessary to pack something. But our concern went beyond mechanical performance. So we think about microbial protection. So we created Alpfilm Protect.The product is made in just one layer and is not mixed with other types of materials — just one of the basic principles of sustainability. But as we know that sustainability doesn't stop at production, we feel obliged to take a step forward: make the circularity process for flexible materials, mainly PVC plastic film. Because it is a very light material and usually contains weight labels, the process ends up becoming very artisanal.

With all this in mind, we went in search of cooperatives that had this product. Together with Braskem's technical assistance, specifically that of Emerson Madaleno, we were able to produce a flexible filament to be used in the fashion industry with our first partner in the development of shoes, Patrícia Camacho.”

Alessandra Zambaldi

AlpFilm's Market and Export Intelligence

About AlpFilm

We are one of the largest PVC plastic film manufacturers in Brazil, with a monthly production of 450 tons of material. Since 2014, the company has been selling plastic film with silver microparticles for food packaging in supermarkets and for domestic use, with the aim of providing protection against fungi and bacteria, helping to increase food durability, freshness and health.AlpFilm and social responsibility

We have a partnership with NGO Food Bank, which collects food that would be discarded — but still suitable for human consumption — and distributes it to people in socially vulnerable situations throughout the city of São Paulo.teaching new ways

One of the purposes of the project is to open new paths for recycling in Brazil. By showing that post-consumer plastic film can also be recycled, people will have a new opportunity to send garbage to the correct place of disposal. In addition, together with a new network of partners, we will expand recycling processes in Brazil.